Servo-assisted Solenoid Valves

Chamber:

Pressure is equalized in the chamber and is the space into which the diaphragm or piston recedes to allow flow.

Pilot channels:

Allow fluid to move out of the chamber and from the pilot to downstream to enable the fluid to assist in opening the main seal.

Equalization hole/channel:

Ensures that the inlet pressure and the pressure in the chamber above the diaphragm or piston are slowly equalised in order to close the valve.

Above the seat flow:

In all pilot-controlled valves, the flow takes place above the valve seat.

Spring:

The spring in the chamber supports the media pressure during closing of the valve. In valves that are exposed to aggressive chemical fluids, the spring is avoided. The media pressure alone then closes the valve.

Main Orifice:

The area on which the media pressure will act and the gap through which the media will flow when the valve is energized. Along with the contours of the valve it governs the pressure drop and the flow rate of the valve.

Process connections:

Many fluidic sizes and connections are available to meet local geographic or industry-specific standards.

Seal:

A soft material, either a diaphragm or a flat seal attached to the underside of a solid piston or a plunger which halts the flow of fluid from one side of the main orifice to the other.

Seat:

A raised area at the diameter that concentrates the pressure of the seal. Press-fit seats made of VA are used in case of potential abrasion or cavitation.

Servo-assisted: Diaphragm valve with plunger pilot control

Function:

This functioning principle uses a direct-acting plunger valve as the pilot valve and a flexible diaphragm as the seal for the main seat. As soon as the pilot valve opens, the fluid chamber above the diaphragm is emptied. The media pressure within the diaphragm raises the diaphragm and opens the valve so that the medium can flow. If the pilot valve is closed, the media pressure above the diaphragm builds up again through the small compensation opening and the closing process is supported additionally by the compression spring. Minimal differential pressure between the inlet and outlet is necessary for complete opening and closing.

Application:

The main areas of application for this pilot-controlled solenoid diaphragm valve are clean liquid or gaseous media such as compressed air, water, hydraulic oils, etc. The small pilot valve makes them less expensive than direct-acting valves for use with higher pressures and larger diameters.

Special features:

Since pilot-controlled valves (also: servo-assisted valves) have only a small pressure equalisation hole in the diaphragm, they are susceptible to dirt particles and crystallising media, which can clog the hole. Ex or low power versions are virtually unproblematic compared with direct-acting valves since the pilot control valve only has lower power consumption.

Servo-assisted: Coupled diaphragm solenoid valve with plunger pilot control

Function:

This functioning principle uses a direct-acting plunger valve as the pilot valve and a flexible diaphragm as the main seal. As soon as the pilot valve opens, the fluid chamber above the diaphragm is emptied. The media pressure within the diaphragm raises the diaphragm and opens the valve so that the medium can flow. If the pilot valve is closed, the media pressure above the diaphragm builds up again through the small compensation opening and the closing process is supported additionally by the compression spring. This valve type can switch without differential pressure since the diaphragm holder of the main valve is connected to the armature rigidly or by means of a spring. The pilot valve alone is capable of partially opening the main valve.

Application:

The main areas of application for pilot-controlled diaphragm solenoid valves are liquid or gaseous media such as compressed air, water and hydraulic oils in closed circuits in which little or no differential pressure is present for opening and closing.

Special features:

All the DC versions feature energy-saving power reduction.

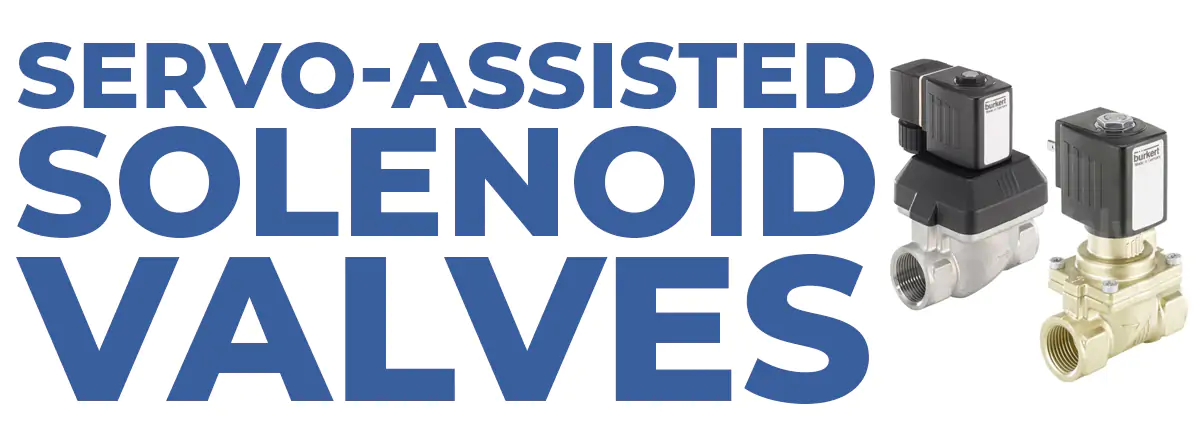

Servo-assisted: Piston valve with plunger pilot control

Function:

This operating method uses a direct-acting plunger valve as the pilot valve and the main valve seal located on the base of a solid piston which moves vertically through a cylindrical chamber. The fluid chamber above the piston is relieved when the pilot opens. The medium pressure beneath the piston lifts the piston and opens the valve allowing flow. When the pilot valve is closed, the medium pressure is allowed to build up again above the piston through the equalizing orifice in the piston body and closing is aided by the force of the compression spring. These valves require a minimum pressure differential to exist between the inlet port and the outlet port and are limited to controlling the same clean media as the non-isolated plunger pilot.

Application:

The main area of application for this servo-assisted solenoid-piston valve is the reliable control of compressed air, neutral gases and steam up to 160 °C with a high number of strokes in diameters from DN 12 to 50 mm. Piston valves are especially robust for switching of compressible media such as gas and steam.

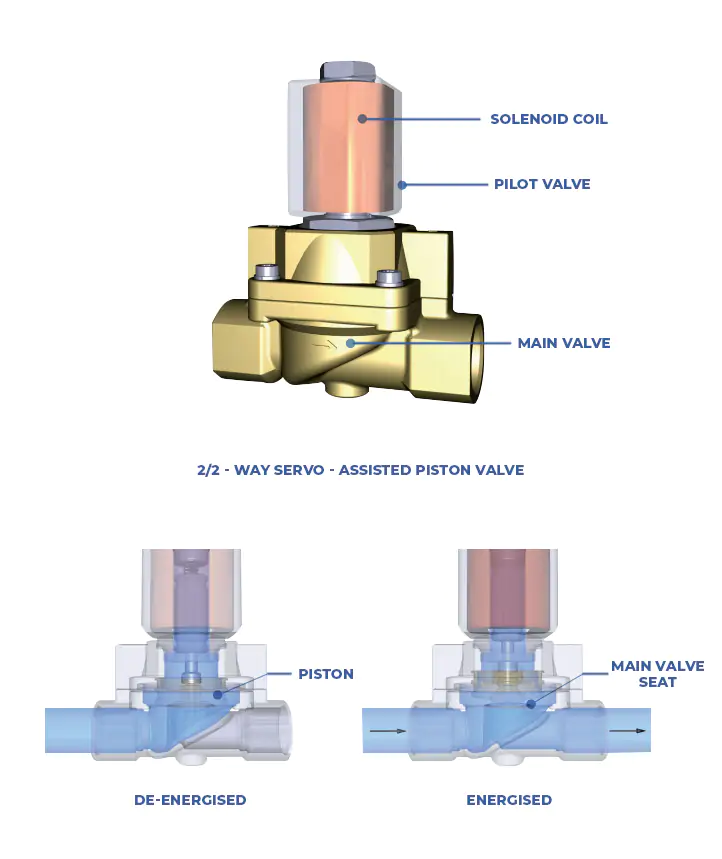

Servo-assisted: Fixed coupled piston valve with plunger pilot control

Function:

This functioning principle uses a direct-acting plunger valve as the pilot valve and a fixed coupled piston as the main seal. In closed state, the piston seals the main valve seat. If the valve is energised, the pilot valve opens the pilot seat. The media pressure and the armature of the pilot valve cause the piston to move upward and release the main valve seat. If the pilot valve is switched off, this design provides for slow, impact-free closing of the valve. As opposed to the other pilot-controlled valve models, these valve types switch also without differential pressure, since the pilot valve alone opens the main valve seat.

Application:

Fixed coupled valves are used in applications with little or no differential pressure since the force of the pilot control valve alone is also enough to open the main seat. Neutral gases and steam are among the primary applications.

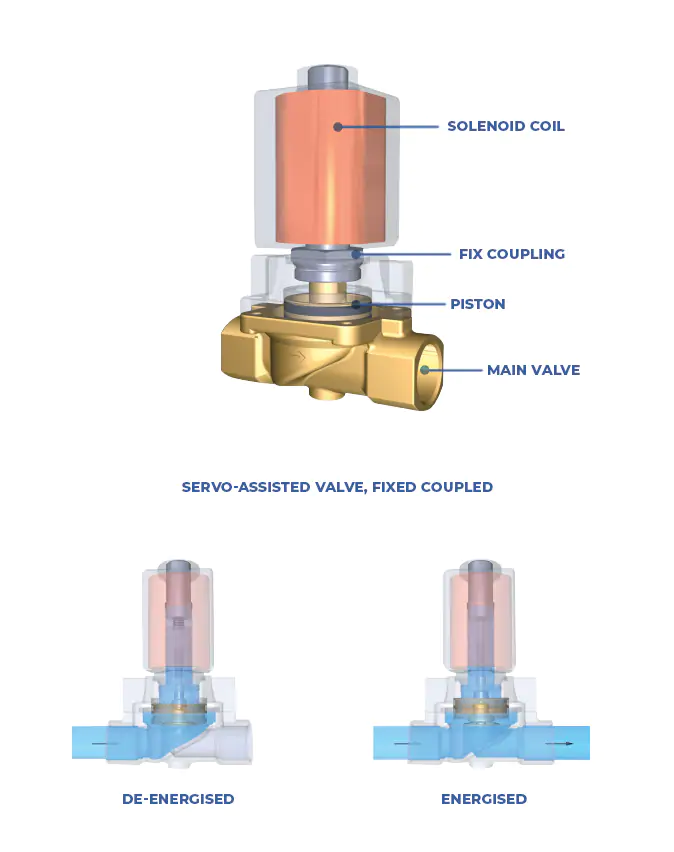

Servo-assisted: Diaphragm /piston valve with pivoted armature pilot control

Function:

This unique functioning principle uses a media separated, direct-acting 3/2-way valve as the pilot valve, while the seal of the main valve is a larger flexible diaphragm or a piston. As soon as the pilot valve opens, the chamber above the piston opens so that the media pressure raises the diaphragm, therefore allowing the media to flow. If the pilot valve is closed, the channel to the outlet side is also closed and the media pressure can build up again through the inlet-side pilot channel. The closing process is additionally supported by the compression spring. Minimal differential pressure between the inlet and outlet is needed for complete opening and closing.

Application:

The main area of application for this unusual valve is the reliable switching of mildly contaminated and aggressive gases and fluids for diameters DN 10 to 65 mm. This type is designed for universal use. With this valve type, there is very little danger of clogging since the actuator and media chamber are separated by a diaphragm.

Special features:

In some versions of this valve type the opening and closing speed can be adapted to the application and configured for continuous adjustment.

View all our Normally Closed Servo-Assisted Brass Solenoid Valves here >>

Normally Open Servo-Assisted Brass Solenoid Valves here >>

Normally Closed Servo-Assisted Stainless Steel Solenoid Valves here >>

Normally Open Servo-Assisted Stainless Steel Solenoid Valves here >>